Oregon Aero® Seating Systems Overview

Oregon Aero designs and builds seating systems for individual, and OEM customers. For OEMS we manufacture complete High-G® Safety Seat assemblies. The High-G seat includes both the seat frame and cushion system. For individuals, we can upgrade your certified seating through our FAA approved repair station. We also build seat cushions for homebuilt and experimental aircraft. Oregon Aero engineering goes beyond the seat, taking into account variables of space, interface, application, and specific customer requirements. We also provide custom upholstery in your choice of leather, vinyl, fabric, and sheepskin materials. Custom embroidery options are available to personalize your seats.

Features and Benefits

Your aircraft seat doesn't have to sit like a stone.

- Provides maximum comfort for every occupant

- Shifts hips, pelvis and back into the pain-free position

- Minimizes lower back pain caused by prolonged sitting

- Reduces fatigue for better concentration and focus

- Helps maintain leg circulation during long flights

- Eliminate distractions caused by seat pain and discomfort

- Improves crew endurance for missions that go into overtime

- Cushions conform to the individual occupant’s shape

- Engineered for the intended purpose and environment

- Can be customized to suit specific needs

- Equally effective in cold or warm temperatures

- Durable cushions resist deformation over time

- Meets all applicable FAA requirements and regulations

- Backed by more than 30 years of experience

- Designed and Manufactured in the U.S.A.

The Secret to Seating Comfort

When our parents told us to “Sit up straight!” they were right. Sitting straight does help create a smooth lumbar curve essential for seating comfort. However, the seat itself bears most of the responsibility. For long-duration comfort the seat must be shaped to provide proper hip and pelvic alignment and provide the correct lumbar curvature to set the position of the head and shoulders. Also, the cushion material must distribute the occupants weight evenly across contact surfaces to maintain unrestricted blood flow. Any seat that does not provide all of these conditions will be a source of pain and discomfort.

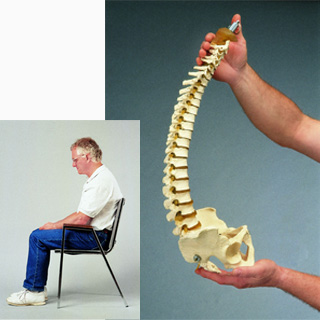

Uncomfortable Sitting Position

Why is my seat so uncomfortable?

Proper spinal alignment is essential for seating comfort. Unfortunately, most seats make it impossible to sit correctly. The blame usually goes to the lumbar support—or lack of. However, when we sit in a conventional seat the pelvis is rotated back and down which flattens the lumbar spine and compresses the anterior (front) of the disks. From this position our natural instinct is to slouch and no amount of lumbar support will force the spine into the comfortable sitting position.

Comfortable Sitting Position

How are Oregon Aero seats different?

Oregon Aero cushions are built piece by piece using as many as 11 different materials placed according to their behavior. The actual layout depends on the seat and application. All Oregon Aero seat cushions rotate your pelvis forward creating a smooth lumbar curve which is stabilized by a gentle lumbar support. In this position your head and shoulders to shift effortlessly into the upright position. The result is no more seat pain.

In addition to comfort our Visco-Elastic™ foam material supports the occupant’s weight evenly, allows for unrestricted blood flow, conforms to the occupant’s shape, and acclimates to body temperature and pressure.